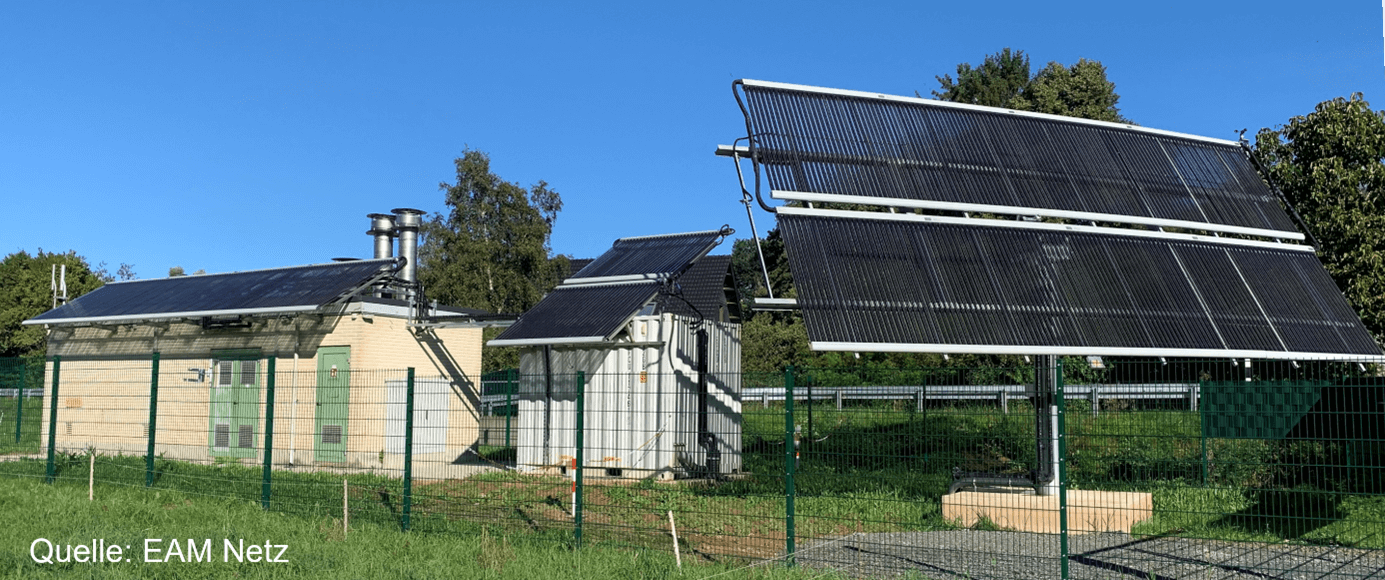

Solar heat supplies the gas pressure regulating and metering station (GPRMS) Braunshausen of EAM Netz GmbH in Hesse. The network operator had a 48 kWth solar thermal system installed at the station to support the heating system. The solar heating system is characterised by its innovative and efficient design. The collector field consists of three different fields, each with different characteristics. A drainback collector array with a total area of 9.8 m² is located on the roof of the container. Another collector array is installed on a 2-axis tracker and covers a total area of 39.2 m². Both the drainback and tracker collector arrays are connected to a shared 3.8 m³ heat storage tank. There is also a collector array with a direct connection to the heating circuit of the station, with an area of 19.6 m².

Solar process heat for the Rothaus brewery

The passion for brewing beer has been cultivated at the Badische Staatsbrauerei Rothaus AG since 1791. Traditional craftsmanship, the Rothaus brewing process, the best regional raw materials and crystal-clear, soft water from seven of the company’s own springs are the perfect basis for the fresh quality beers such as the popular Tannenzäpfle. Rothaus, Germany’s highest located brewery in Grafenhausen in the Upper Black Forest at an altitude of 1,000 m, currently employs around 250 people.

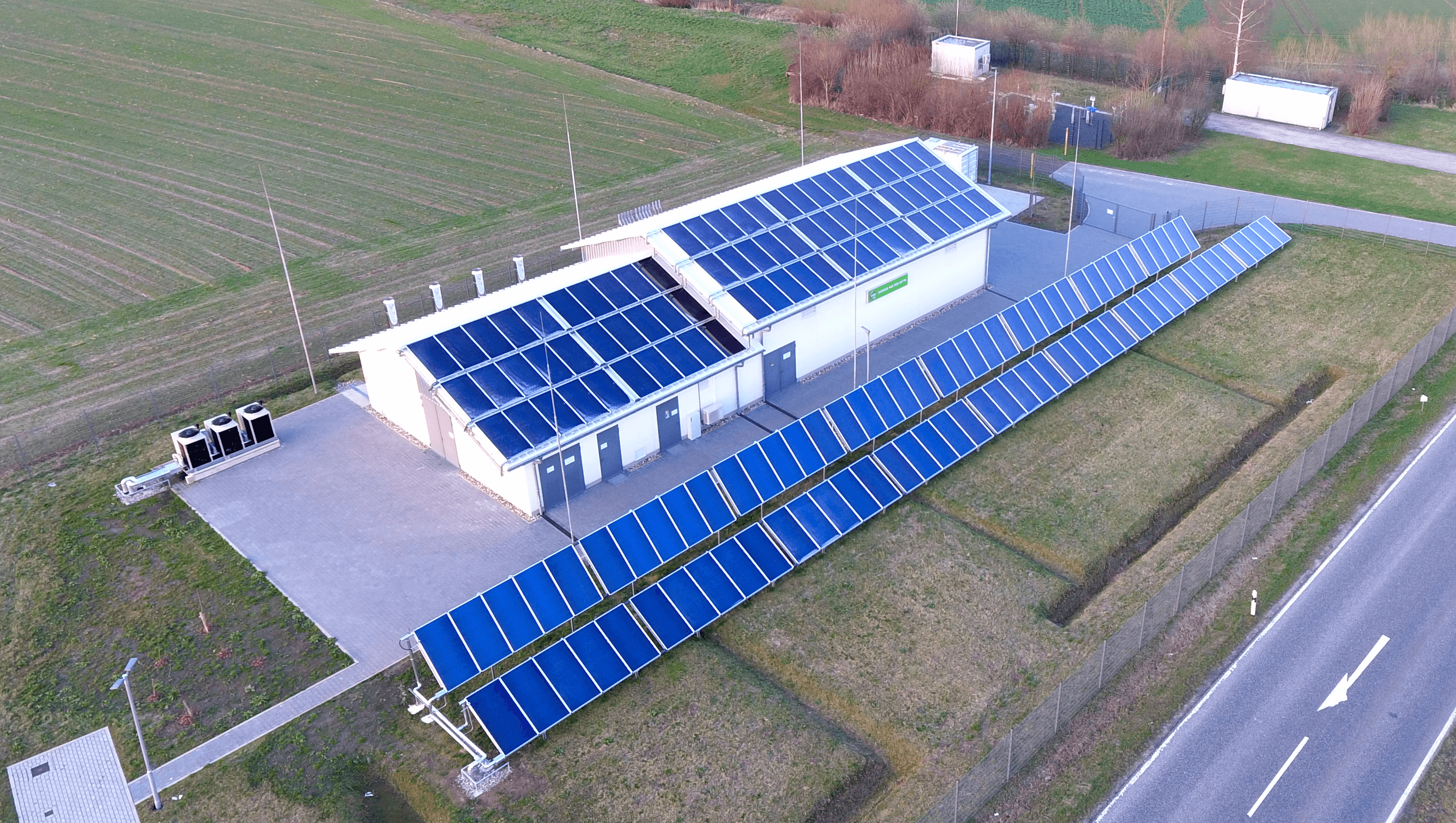

Innovative gas pressure regulating station Dillenburg

The gas pressure regulating and metering station (GPRMS) Dillenburg operated by EAM Netz GmbH supplies part of the Lahn-Dill district in Hesse (Germany) with natural gas. At the station, the pressure of the incoming natural gas is reduced from 44 bar to 4.5 bar. […]

Solar paper mill

Condat is part of the Lecta Group, one of Europe’s leading manufacturers and distributors of specialty papers for labels and flexible packaging, coated and uncoated papers for publishing and promotional printing and other print media. The Condat factory in Lardin-Saint-Lazare, with about 500 employees, has an annual production capacity of 450,000 tons of coated paper, with a high energy requirement, mainly due to the direct use of steam in the production processes.

Gas pressure regulation with solar heat

The gas pressure regulating and measuring station (GPRS) Ostheim owned by the company Energienetz Mitte (ENM) has a heat demand of about 1,900 MWh/a for preheating the natural gas, which is throttled in the station from 90 bar to 16 bar in order to feed it into the downstream natural gas network. The heat requirement is due to the fact that the natural gas cools during expansion and must therefore be heated up by around 30 K before the throttle used for the expansion. Without the preheating of the natural gas before the expansion, the freezing point in the throttle would be undercut, which would lead to technical problems due to condensate, ice formation and the deposition of individual gas fractions in the pipelines.

Vacuum Tube Collectors at Colonia Spezialfahrzeuge

With a fleet of more than 250 vehicles, it is one of the largest providers of crane services and heavy load transports in North Rhine-Westphalia. With a fleet of more than 250 vehicles, it is one of the largest providers of crane services and heavy load transports in North Rhine-Westphalia. Because of the steady growth of the business, a new large shop with a truck wash for vehicles with a length of up to 23 metres was built. Since a solar thermal plant had been considered in the planning period already, building the collector field and components took less than two months. The components were delivered ready to use and directly integrated to the system.

[…]

Tobacco Production with Solar Process Heat

Japan Tobacco International is the fourth biggest tobacco product manufacturer in the world with a large number of production sites, one of which is in Jordan and employs around 200 people. The tobacco production requires steam for drying purposes and furthermore, due to the geographic location of the production site, there is a high demand in air-conditioning. The steam has been supplied by a LPG-fuelled boiler and an electric compression refrigeration machine was used for the cold production. In November 2017 a solar process heat plant was installed. The Fresnel collector-field with an aperture-area of 1,254 m2 is installed on the factory’s rooftop and runs in direct-steam mode: water is pumped into the absorber pipe, steamed partly there, and fed as a water-steam-mixture into the steam drum. The steam accumulates in the upper part of the drum from where it is fed into the steam circuit while the un-steamed water is re-circulated and fed, together with feed water, to the absorber pipes again. The collector field and the steam drum can be run at temperatures of up to 220°C, which is significantly above the required temperature level. Therefore, at the given volume of the steam drum, more energy can be stored. The integration into the existing steam circuit is regulated by a pressure control. Solar produced steam is used with priority while the fossil boiler only covers the remaining heat demand.

[…]

Wood Chips and Organic Milk from Bavaria

The dairy farm “Zum Marx”, run by the family Westenrieder and their two employees, dries wood chips and hay and produces organic milk as well as further dairy products for sale.

The company’s complete heat demand is covered by a solar plant, which was installed in 2015, and a wood chip boiler. The energy system uses air collectors and 160 m³ of wood chips per year, which are dried by the solar plant. The collector field with CCS+ air collectors by the company CONA and an area of 156 m² has a thermal power of up to 114 kW and was integrated into the rooftop of the drying facility.

[…]

Air Collectors for Hay-Milk from the Bavarian Forest

The agricultural family business Mühlbauer in the Bavarian Forest switched their production to hay-milk and simultaneously installed a drying plant heated by air collectors. The goal was not only to secure the business’s livelihood but also to contribute to animal welfare. Natural hay rich in herbs promotes the health of the cows, which in turn give more milk of very high-quality rich in Omega-3 fatty acids.

[…]

Fresnel-Collectors at RAM Pharma

The company RAM Pharma in Sahab, Jordan, was founded 1992. Today around 270 employees produce different pharmaceutical products for the national and international market. There is a great process heat demand for drying and sterilisation processes which is, besides by the existing diesel driven boiler with 450 kW of thermal power, now also met by Fresnel-collectors. There is a great process heat demand for drying and sterilisation processes which is, besides by the existing diesel driven boiler with 450 kW of thermal power, now also met by Fresnel-collectors. The steam is supplied at 160°C. Furthermore, there is a hot-water-boiler, which is used for facility heating during winter. The steam is supplied at 160°C. Furthermore, there is a hot-water-boiler, which is used for facility heating during winter.

[…]

You must be logged in to post a comment.